What industrial painting entails

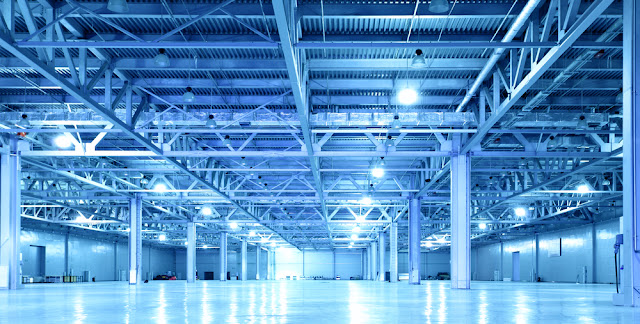

Maintaining your

property regularly in an industrial establishment is very important. This is a

business that receives a number of clients on a daily basis. It is obvious that

cleanliness is next to godliness hence you have to keep your buildings clean

and well maintained. This is what creates the first impression on your clients’

minds whenever they pay you a visit. Moreover, your employees can only be more

productive when they are working in a clean and well maintained

environment. Find out more what

industrial painting entails;

Industrial

painting entails utilizing a lot of methods especially when coating the

surfaces to come up with the desired results.

This project is a bit different from residential painting as it does not

only involve applying the paint using a simple brush as well as a roller. Industrial painting requires proper

preparation on the surfaces prior to applying the paint.

Without proper

preparation on the surfaces, the paint is likely to wear and tear quite fast

hence making the whole process expensive.

For instance, industrial painting involves getting rid of the previous

paint, dusting the surfaces, repairing the cracks as well as the chips then

washing the surfaces. Did you that

removing the previous paint require a specialized skill?

In a

manufacturing plant, there are high chances of grease, oil and chemical

spillage as well as other tough stain appearing on the surfaces. In order to get rid of such dirt, you need an

ultra-pressure water jet. Using hot water is an added advantage especially when

it comes to removing grit among other stains. In simple reality, industrial

painting requires a reputable and well equipped professional who has handled

such project before.

There are

different methods that are considered in industrial painting other than using a

brush and roller. There are other techniques such as powder coating where

particles of dry paint are applied on a surface. The powder is

electrostatically charged hence they are easily held on the surfaces. Afterwards, heat will be applied on the

surfaces so that the powder can now flow together and form the required coat.

Industrial painting also involves roll coating which is suitable for metal surfaces. Due to the fact that it is a continuous process, this aspect makes it a high speed method that has been considered by most contractors. The process is eco-friendly and quite cost effective.

Another process

that has also been considered mostly by industrial painting contractors is

spray coating. This method is popular as

it is easy and saves time. Did you know

that this process has been used successfully to deliver resins as well as

sealants under high pressure?

In the

aforesaid, we can attest to the fact that industrial painting involves a lot of

processes and preparations as mentioned in the article. These processes keep

changing as the technology advances every single day that is why professional

in this line of service should keep on top of all the latest methods that are

suitable to the current generation.

Comments

Post a Comment